PSAI Members Remember Painting Portable Units

Can you imagine hearing these phrases today?

- “After the paint dries, we can deliver those portable restrooms.”

- “These units are all cleaned, now they just need to be touched up with a little paint and they will be ready to go.”

- “We need to buy more paintbrushes.”

The first portable restrooms were made of wood, usually constructed by the operators themselves in their own yards.

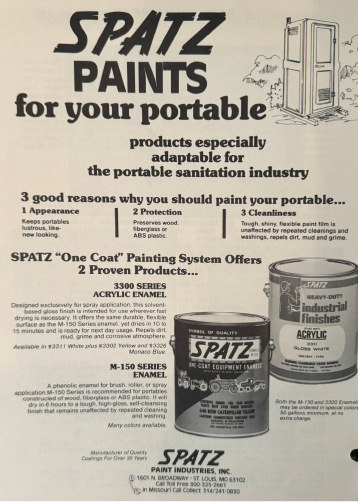

One early supplier member of the organization then known as PSA (Portable Sanitation Association) was Spatz Paints. Based in St. Louis, Missouri, this company filled a need for our industry. Units were painted to protect the wood, to project a clean image, and to advertise the company.

Spatz began supporting the PSA in September 1976 and continued their support into the late 1980s.

Founded in 1946 in St. Louis by Michael Spatz, the company specialized in paints and primers that prevented corrosion and weathering. Their products were used in heavy-duty applications and could be used for painting LP gas tanks, ornamental iron fabrications, mining equipment, water tanks, and drive-in movie screens. Interestingly, the gloss and sheen of Spatz paints on movie screens—in addition to its resistance to heat, moisture, and cold—were ideal for this application.

As can be seen from the ad below for the 1982 PSAI Annual Meeting and Trade Show in San Francisco, Spatz Paints had expanded their focus to both fiberglass and plastic units.

While we are not sure of their success with paint for plastic units, fiberglass units would have been a successful marketplace. Fiberglass units could be easily painted—either to refurbish the standard white color or to differentiate a company’s units from their competition by the choice of another color.

With the transition to plastic units and a multitude of colors and color combinations, Spatz Paints exited our industry, but they continue their success today in a multitude of markets including commercial and residential applications.

Two of our PSAI longtime members share their experiences with painting units:

Elton Tamplin, South Central Regional Sales Manager for PolyJohn, remembers:

“I started in this industry in April 1979, right out of high school. I immediately went to work for a Dallas-Fort Worth company—Chem Can—owned by C.W. Halbert. My uncle Bob Young was the shop manager. We built units out of ¾-inch thick marine-grade plywood with a fiberglass tank and urinal. They weighed around 400 pounds. When units would come back off jobs, we would clean, repair, and put a fresh coat of paint on them even if they didn’t need it. I told my uncle many times that the paint was just making them a little heavier each time—but they always looked good.”

Jeff Wolfarth, Mr. John of Pittsburgh Vice-President, shares:

“When I worked for Mr. John during the summers during high school, my job was to repair and paint wooden units. We would stockpile 20 or so and I would come in every other Saturday and paint them all. The color was a dark reddish brown called oxide red enamel and somehow, we called it ‘tinners red.’ At one point, I did not have any clothes that didn’t have that color paint on them. Because I was young and had really no experience spray painting, I quite often spent the following Monday buffing out the neighboring company cars and trucks that had gotten over-spray on them.”

It was a monumental day for our industry when painting units became obsolete.

For even more interesting facts on the history of our Industry and of our Association, click on the links below and order your History Book today. All proceeds benefit the PSAI Scholarship Program.