The Early Years of Service Trucks

The founders of our industry overcame many obstacles and challenges to bring our businesses to where they are today. Service trucks are no exception. From the first motorized sewage truck patent in 1907 by American inventor George Blickensderfer to today, service trucks have undergone a remarkable transformation.

While World War II contributed to the founding of the portable restroom industry, it also advanced tank truck technology. Tank trucks were needed and used to transport fuel both to the front lines for tanks and trucks as well as to airfields for planes and to ports for ships.

Engine Technology

What type of engines and fuel did these tank trucks use? Surprisingly, they were powered by gasoline—not diesel. The first service trucks in our industry were therefore gasoline engines, not nearly as powerful as they are today.

Diesel fuel and diesel engines gained efficiency in the 1960s; however, it was 1893 when Rudolf Diesel received a patent for this internal combustion engine—and fuel—that now carries his name.

It took many years of hard work and development for the efficient and powerful diesel engine to be perfected. In fact, it took another 15 years or so for diesel pickup trucks to be offered. In 1978, both Chevrolet and Dodge launched their first diesel models, and it was 1983 for Ford.

Vacuum Technology

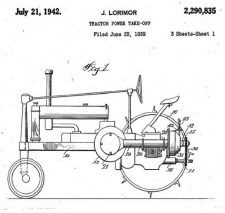

As far as vacuum technology, in 1942 the patent for a power take-off (PTO) valve was issued—as seen in the illustration below—and in 1945 Cockshutt Farm Equipment developed a “live” PTO that controlled vacuum “independent” of the tractor’s engine.

These early PTOs only powered small farm engines, and they did not become viable for our industry until the mid-1960s to early 1970s. So, for the first 30 years of industry, the truck engine’s manifold powered the system that created the vacuum to pump out portable restrooms.

Challenges with Truck Manifold-Powered Vacuum Pumps

Our predecessors in this industry faced many challenges with this early method of pumping units:

- While driving down the road, the truck’s engine would suck the air out of the tank and greatly reduce the vacuum pressure in the waste tank, upon arrival at the next unit, valuable time was spent building back pressure in the tank.

- The cold air flowing back from the vacuum tank would hit the warm engine valves of the truck, causing a slow and continual degradation of these parts. About once a year, without fail, a valve job would have to be done on the engine —an investment of both money and truck downtime.

- The worst fear of this process was overfilling the waste tank and the overflow traveling directly to the truck’s engine! Engine damage and/or destruction was the ultimate price to pay for overfilling the tank. (How many drivers lost their jobs over this error in judgment?)

Personal Accounts

Here are two testimonials from longtime PSAI members (Wes Tuttle with Masport and Jeff Wolfarth with Mr John of Pittsburgh) that clearly illustrate the challenges that those in our industry faced before PTOs became the standard.

Wes Tuttle shares two important points:

- “A loss of vacuum can cause the engine to run rough. To help overcome this, many people installed a pull cable to the carburetor throttle to raise the engine RPM which helped produce more vacuum and help overcome the rough idle conditions of vacuum loss.”

- “Pulling waste or moisture into the truck engine was also a major risk. The primary trap in the top of the tank has a limited ability to stop the waste flow so many people who did this risked bending valves or hydro locking the entire engine. Overfilling the tank was a major problem. Operators have tried all kinds of traps to help—like air dryers for air compressors, racquet balls in a piece of PVC pipe plumbed similar to modern secondary scrubbers—but none of them were overly successful.”

Washington, D.C. Note the small tank size compared to today’s models.

Jeff Wolfarth shares similar experiences:

“We used a ping pong ball in a Mason jar to try to control the backflow of waste into the truck’s engine. The good thing was, as long as the truck was running you had a vacuum. The bad thing was sometimes too much vacuum and it would crush the ping-pong ball or worse the mason jar would implode.

“At least 2 times when I was a service tech the truck tank was overfull, it bypassed the traps and waste got into the engine and stalled it out. Our mechanic would come out with 8 new spark plugs, remove the old ones, then I would turn the engine over and watch the waste shooting out of the spark plug holes! The mechanic installed the new plugs and after a little cranking, the engine would fire up. It ran rough and the exhaust smelled awful for a while, but I used that same truck the next day.

“Our first diesel truck was in 1980 and that was our first experience with a vacuum pump mounted under the hood. It was mounted on a bracket with a fan belt, and we used an AC clutch to turn the pump on and off in the cab—that was state of the art!”

PTO technology greatly decreased the amount of time for pumping. As Bruce Curry with American Tank Company shares in our PSAI History Book, “It was not uncommon for a septic tank that took 2 hours to be pumped using the truck engine manifold to now be pumped in 20 minutes using a PTO.”

With the combination of diesel engines and powerful PTO pumps, tank technology also evolved as larger tanks were now viable. In recent years, aluminum has allowed lighter-weight tanks and better fuel mileage.

What Does the Future Hold?

- When will electric-powered service vehicles become the standard?

- Will robotics become involved in the pumping process?

- How will the truck’s waste be treated when released from the truck?

- Keep experimenting with ideas and who knows?

For even more interesting facts on the history of our Industry and of our Association, click on the link below and order your History Book today. All proceeds benefit the PSAI Scholarship Program.